Your vehicle gate is more than a barrier. It decides who gets near people, product, and critical assets. For many manufacturing sites, that decision still relies on a single method at a single point in time. A badge scan or a visual check might work most days, but it leaves gaps during shift change, after hours, and in busy mixed traffic.

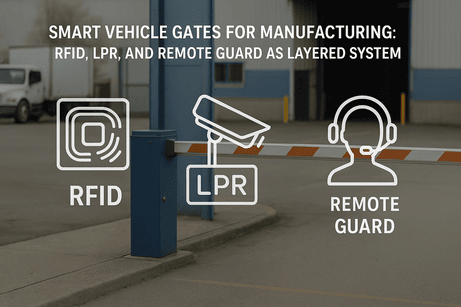

A better approach is a layered gate system that blends RFID access control, license plate recognition, and remote video monitoring with live operator support. In other words, fast for the known, flexible for the unknown, and verifiable every time. This guide explains how to design that layered approach, where each technology shines, and how to integrate it with factory access control and plant surveillance systems.

k

k

What a layered gate really means

Layered does not mean adding gadgets. It means combining signals and responses so that one control backs up another.

-

RFID identifies approved vehicles and drivers quickly

-

LPR verifies plates against allow lists and schedules

-

Remote guard operators handle exceptions, deter intruders with live audio, and coordinate response

-

Video, intercoms, and access logs tie it all together for audits and investigations

When designed well, the system keeps your queue moving while improving industrial site security.

k

k

The three core layers

RFID for known traffic

Best for: employees, fleet vehicles, recurring carriers

Strengths: speed, high throughput, clean audit trail

Considerations: pair with driver identity when risk is higher, tune read zones to avoid cross-lane reads

LPR for verification and visitors

Best for: contractors, vendors, one-time carriers, will-call pickups

Strengths: visual confirmation, plate history, schedule matching

Considerations: lighting and camera placement matter, keep allowlists current, handle damaged or dirty plates with a secondary check

Remote guard for exceptions

Best for: after hours, tailgating attempts, unknown vehicles, policy exceptions

Strengths: human judgment, live talk-down deterrence, real-time escalation

Considerations: require clear runbooks and service levels, ensure good audio quality and reliable connectivity

k

k

How the layers work together

Day shift employee entry

RFID reads the tag and opens the gate. LPR logs the plate and links to the event. No operator needed and the queue keeps moving.

Contractor at 6 a.m. with scheduled work

LPR matches the plate to the appointment window and expected door assignment. The system opens or routes to a remote guard for quick ID verification if needed. Access logs note the purpose of visit.

Unknown vehicle after hours

Motion analytics trigger a call-up. A remote operator views the scene, speaks through the intercom, requests ID, and denies access if the visitor is not authorized. If behavior is suspicious, the operator alerts the on-call contact and law enforcement per the playbook.

Attempted tailgating behind an approved truck

RFID grants access to vehicle one. LPR flags a second plate without authorization. The gate closes, a warning plays, and the event is bookmarked for review.

k

k

Integrations that make the gate smarter

-

Factory access control: link gate decisions to interior doors and cage entries so a denied vehicle cannot pivot to a side door

-

Plant surveillance systems: auto-bookmark video for each gate event and surface the live view during exceptions

-

Dock and yard systems: tie LPR to appointments so carriers are directed to the right door and off-schedule arrivals are handled fast

-

Mass notification and intercoms: push alerts for suspicious activity and enable two-way talk at the pedestal

-

SIEM or incident software: centralize alarms, clips, and notes for audits and insurer reviews

k

k

Design patterns for different manufacturing sites

Single gate, high employee volume

RFID as the primary, LPR for verification and plate history, remote guard on demand for stalled reads or policy exceptions. Add a bypass lane for visitors to prevent queues.

Multi-building campus with vendor traffic

RFID for employees, LPR tied to dock scheduling for carriers, remote guard overnight. Use pre-registration links to speed contractor access and print temporary credentials at a kiosk.

High-risk or regulated facility

RFID plus driver ID at the pedestal, LPR for dual verification, remote guard for video ID check, and random secondary screening. Automatically lock interior gates if a gate alarm triggers.

k

k

Reducing false alarms without missing real threats

-

Use human and vehicle analytics, not raw motion

-

Calibrate read zones for RFID to avoid cross-lane scans

-

Add proper lighting and capture angles for LPR

-

Mask public roads and moving foliage in camera fields of view

-

Write simple operator runbooks with timing targets for talk-down and dispatch

-

Review exceptions weekly to tune allow lists and schedules

k

k

Metrics that prove value

-

Gate cycle time by traffic type

-

Exceptions resolved without on-site roll-outs

-

Tailgating attempts detected and prevented

-

After hours incidents deterred by live audio

-

Dock on-time performance when LPR is tied to scheduling

-

Investigation time saved using linked video and access logs

-

Insurance and audit findings related to perimeter events

These numbers make a strong case during budget season and demonstrate real outcomes for safety systems for manufacturing.

k

k

Implementation checklist

-

Map gate lanes, approaches, and lighting

-

Define traffic types and required verification steps for each

-

Place RFID readers and tune power and angles

-

Install LPR cameras with proper illumination and plate angles

-

Add intercoms, speakers, and clear signage at pedestals

-

Connect video, access control, and scheduling data to one view

-

Write operator runbooks with contacts and escalation rules

-

Pilot on one gate, measure queue times and exceptions, then expand

k

k

How SSP helps

SSP designs and deploys layered vehicle gate security for manufacturers that need speed without sacrificing control. We integrate RFID access control, LPR, and remote video monitoring with your existing surveillance and access platforms, then build the runbooks and reporting that teams actually use. The result is faster throughput, cleaner audits, and stronger industrial site security around the clock.

Learn how SSP helps manufacturers protect operations, people, and property.

If you want a quick gate assessment and a phased upgrade plan, we can map your lanes and propose a solution that fits your traffic, risk, and budget.