Gas detection systems are a staple in manufacturing—especially in environments where chemicals, confined spaces, or combustible materials are present. But even the most advanced sensors don’t do much good if they can’t trigger a broader response. That’s where many facilities fall short.

They treat gas detection and security as two separate systems. One monitors for risk. The other controls who gets in, what gets locked down, and how people are notified. Without integration, your gas detection system may be doing its job—but your team might still be missing the moment that matters.

This article explores the disconnect between gas detection and access control in manufacturing, why that matters, and how integrating both systems can lead to faster emergency response, stronger compliance, and better safety outcomes across your site.

k

k

The Silo Problem: Safety vs. Security

In many industrial facilities, the safety team owns gas detection and the security team manages access control, intercoms, and surveillance. These systems are often installed at different times, managed by different departments, and rarely integrated.

That leads to situations like this:

-

A gas sensor in a mixing area detects high levels of ammonia.

-

It triggers a local alarm and notifies the safety lead.

-

But the door to the area still opens when someone badges in.

-

The surveillance team sees the alarm light flashing on camera—but they’re not looped into the alert.

-

Security and EHS operate on parallel tracks.

This kind of siloed response creates confusion, slows down evacuation or lockdowns, and makes it harder to identify who was exposed or at risk.

k

k

Why Integration Matters

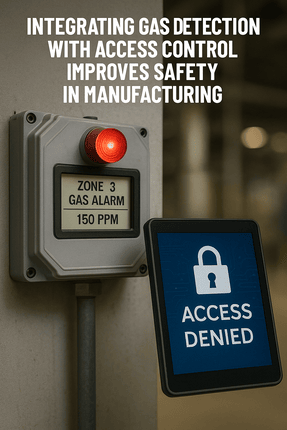

When your gas detection system integrates with access control, surveillance, and facility alerts, the entire response becomes more proactive and automated.

Here’s what that might look like in practice:

-

A sensor detects a gas leak in Zone 3.

-

Access control automatically denies entry to that area.

-

A mass notification goes out to safety and operations teams.

-

Security cameras flag the zone in the live monitoring dashboard.

-

Digital signage near entry doors displays a warning.

-

The event is logged with timestamps and actions taken.

Now, you’re not just relying on someone to see an alert and act. The system enforces safety in real time.

k

k

Key Use Cases in Manufacturing

The benefits of this kind of integration are especially clear in these situations:

Confined Spaces

Before a technician enters a confined space, sensors can verify that the air is within safe levels. If it’s not, the access control system can prevent entry.

Mixing and Chemical Storage Areas

If a gas leak occurs, these areas often need to be evacuated and locked down quickly. An integrated response can initiate both within seconds.

Shift Transitions

Many incidents happen during shift changes when people are moving in and out. Integrating gas detection with security ensures no one walks into danger unknowingly.

k

k

Real Benefits for Safety and Operations

When safety systems and security systems talk to each other, you get:

-

Faster response times

The system takes action immediately without waiting for human input. -

Clearer documentation

You can pull a full timeline of events, badge swipes, gas readings, and responses. -

Improved compliance

Integrated logs support OSHA, ISO, and insurance audit trails. -

Stronger collaboration between EHS and security teams

Everyone works from the same data and triggers.

k

k

How SSP Helps Manufacturers Integrate Systems

At SSP, we work with manufacturing clients to connect the dots between their critical safety infrastructure and their access control systems. Whether you’re using legacy gas sensors or newer smart devices, our team can design a workflow that makes the data actionable.

That includes:

-

Identifying risk zones that require automatic lockdown or entry denial

-

Connecting gas sensors to access control software

-

Programming alerts, signage, or automated responses

-

Providing compliance-ready documentation and training

k

k

Final Thoughts

Your gas detection system is already doing important work. But it shouldn't exist in a vacuum. By integrating it with your access control and security platforms, you can prevent exposure, improve emergency response, and create a safer, smarter manufacturing environment.

If your systems aren’t working together, it’s time to change that.

Want to see how this would work in your facility?

Talk to SSP about building an integrated safety response system.